Ewald Bouwmeister at the IPM Essen 2017

Awareness of plastic use

With the regulations on the use of plastic becoming stricter - and even plastic bans in some countries - the awareness of plastic use among retailers and consumers has increased. "Customers are looking for alternative solutions to plastic, and therefore also for plastic sleeves that is used to pack plants and herbs. There are, however, already paper sleeves on the market, but with this kind of wrapping, the plant isn't that visible anymore which reduces the consumer's ease of making the purchasing decision", says Ewald Bouwmeister of WEBER Verpackungen. So, as a packaging company with many years of experience in Food Retail and the food industry, they saw the opportunity to introduce an alternative sleeve that would not only reduce the use of plastic, but also display the flowers or herbs while at the same time protecting the plant.

Paper-film sleeves

After becoming a well-known packaging supplier in Retail and the food industry, WEBER Verpackungen entered the floriculture industry in 2015. At the end of 2013, WEBER started to think about their production process as they had to re-build one of their packaging machines. "We decided to start producing paper-film sleeves." According to Bouwmeister, WEBER created the first machine that is able to manufacture these paper-film combined sleeves fully automatically. "Usually, they are hand-made in China. Now, with this machine, manual labor is not necessary anymore and one can have the same film-paper sleeve for almost the same price, if not cheaper," he says.

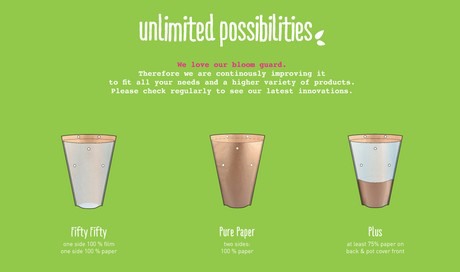

Bloom guard is available in three varieties: Fifty Fifty (one side 100% film and one side 100% paper), Pure Paper (two sides 100 percent paper) and "Plus" (at least 75 percent paper on back and pot cover front).

Bloom guard

The sleeves that roll off this machine are called the bloom guard; a more environmentally friendly and multi-functional sleeve that protects and at the same time can display the flowers or herbs. "It can be made of 100% paper or from a thinner film, making the sleeve more environmentally friendly and in turn using materials more economically. Besides that, inner and outer printing is also possible and thanks to the punched holes, it allows good air circulation and thus a reduced susceptibility to mold. On top of that, the latest innovation - the bloom guard plus - has a pull tab that simplifies the removal of the plant from the top without needing to grasp the flowers, as is the case with conventional plant packaging."

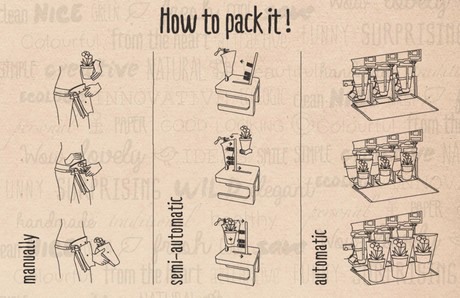

The plants can be sleeved manually, semi-automatic and fully automatic.

Market adoption

WEBER Verpackungen entered the floriculture industry in 2015 and it has not gone unnoticed. In that same year they won the German Packaging award with this bloom guard plus and the year after they presented the product at the IPM Essen for the first time to the international ornamental industry. Afterwards, the demand for this product increased sharply. "At the show, we met a lot of interested growers, retailers and traders and received a lot of requests, and the product quickly ended up on the shelves of some major European retailers and – well known garden centers." Due to this huge acceptance in the market, they had to double their production volume year after year to meet the demand. In the meantime, in 2017, they won the World Packaging Award and they are currently supplying 10 countries, mainly in Western Europe. According to Bouwmeister, the demand is still increasing and WEBER keeps innovating.

IPM Essen 2018

This year, Weber Verpackungen will attend the IPM Essen for the third time. They will put their products on display at their booth in hall 1, booth number 1D12.12.

For more information

WEBER Verpackungen

Ewald Bouwmeister

Email: [email protected]

www.die-tuetenmacher.de or www.bloomguard.de