With three new sticking machines just having been installed, Hishtil is ready for 2020. Over the last years, they have seen an increase in demand - and particularly for their organic herbs. The new ISO machines enable them to increase production while maintaining the same labor amount. FloralDaily.com had the chance to check out the machines at the facility in Afula, where they have all their mother stock and do all vegetative propagation. At this location, they specialize in the propagation of conventional and organic herbs, but they also produce other patio plants and perennials.

Eyal Kleinberger, Maya Avni, and Eitam Argaman in the motherstock greenhouse in Afula in front of the recently installed DryGair machine. "It reduces the air humidity and therefore improves the environment in the greenhouse."

Organic herbs

Organic products are becoming more popular these days and the demand for Hishtil's organic herbs is increasing accordingly. They started producing organic products about a decade ago and in 2010, they established their first organic herbs product line. Over the years, it has been a challenge to comply with all organic rules. “The organic standard is very challenging, mainly due to the need of producing plant propagation material within the standards of both chemical residues and pathogen free. The integration of well-known tools such as chemical control, with innovative models for inspection and effective application enable meeting the strict standards set out in each of the target countries is our main interest”, Nadav Pass, R&D Manager at Hishtil told us in a previous article (click here to read the article on it).

For 2020, Hishtil decided to double the list of their varieties. "We added 30 new varieties to the organic list".

A peek in the greenhouse with mother stock of the organic herbs

Everything that they have organic, they also have available non-organic, or in other words: the conventional assortment. These mother plants are based near the organic mother plants, but in a separate greenhouse. Both greenhouses have their own pipeline, fertilizers, equipment and so on.

'

'

Mother stock of the conventional herbs

From the mother stock to the sticking area

From the mother stock, the cuttings are either directly packed and shipped abroad or brought to the nearby sticking area - which was upgraded earlier this year - to root. 95% of the rooted and unrooted cuttings are produced for worldwide export and 5% is for the local market.

During the peak season - which is around the end of January - 70 workers, particularly women, are busy sticking over 300 varieties in different tray sizes.

In order to handle the increase in demand, Hishtil decided to invest in sticking machines. "Every year, our production grows around 5-15 percent. In order to keep up with the growth, we need a higher production capacity. However, as labor becomes more expensive, increasing the number of workers is a less attractive option. It is important for us to stay and sell our products at a reasonable price level. These machines enable us to improve the efficiency (one person monitors the 3 machines that work double the speed of a worker), depend less on employees, stay at same labor amount and increase production with robots - which we think is the future."

From next year onward, the 3 machines will be used for the big orders. "Currently, the machines are learning the varieties. It takes about one day to teach the machine a new variety, so just before the peak season, the machines will be ready."

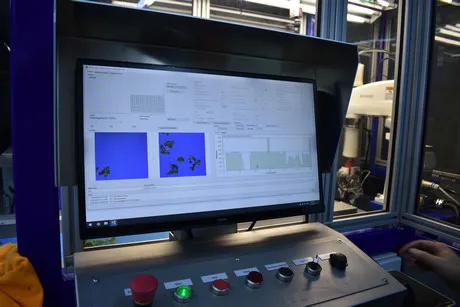

But how does it work? Below an explanation with pictures.

The three sticking machines being handled by one person

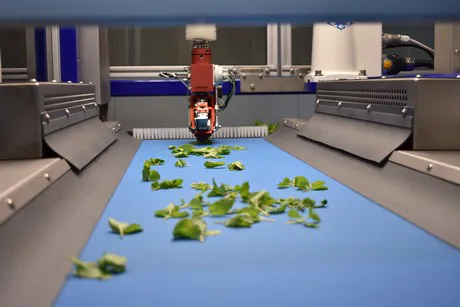

The cuttings being randomly placed on the belt

The 2 cameras on the machine check the cuttings where to pick them up.

The robot arm picking up the cuttings

Cutting being placed in the plugs and the trays are ready to go to the hardening zone.

Rooting area

When the cuttings are stuck into plugs, they go to the hardening area, where the cuttings will get the time to root. Then, when they are ready, they will be prepared to be shipped to all corners of the world.

Rooting area

Cold chain from cuttings to plane

From the moment the cuttings are taken from the mother plants, they will be cooled. "From the cuttings to the plane, the climate is controlled."

Plugs developing roots

Plugs developing roots

Trends

In the organic assortment, rosemary, tarragon, salvia, mint and thyme are the biggest crops. Hishtil works with several breeders and for some varieties, they have exclusivity, like Rosemary Barbecue. "Special about this rosemary variety is the long stems it has. In this way, the consumer can make their own 'barbecue'. Currently, it is our most important variety", says Kleinberger.

Another variety in the organic assortment that is upcoming is lavender. "We see them more and more used for organic oils."

Barbecue

In the conventional assortment, Lavandula is the biggest crop. "The Lavandula varieties cover the worldwide demand. It can flower well in cold and hot climates." The variety list in this Genus is the widest (+50) and also in this category, they have some exclusive varieties like Angustifolia BeeZee. "And there are many more exclusive varieties to come."

Yehezkel's Lookout Point - dedicated to the memory of Yehezkel Dagan (founder of Hishtil) and his adoration of the site of Hishtil Afula. A view of the Yezreel valley, Nazareth Mountains, Mount Tabor and the Lower Galilee Highlands. Click here for a close-up of the text on the right.

Becoming greener

Hishtil is eager to become a more green company and is therefore looking into the options of using green energy. "We want to take advantage of the power station nearby. We would like to use the hot water coming from this station to heat the greenhouse."

For more information:

Hishtil

Maya Avni

Deputy Export Sales Manager and Strategic Project Manager

Email: Elo@hishtil.com

Mobile: +972-50-750-0130

Phone: +972-4-675-5002

Fax: +972-4-640-7583

www.hishtil.com