The rebuilding and expanding of the existing facility of indoor flowers, fresh-cut herbs, and potted edibles grower Rocket Farms in California was completed in May 2021, and is up and running and proved successful. Bosman Van Zaal, together with sister company Crea-Tech International, realized the automated cultivation system for the new living herbs greenhouse.

Turnkey cultivation system based on rolling containers

Greater capacity of production with cultivation system

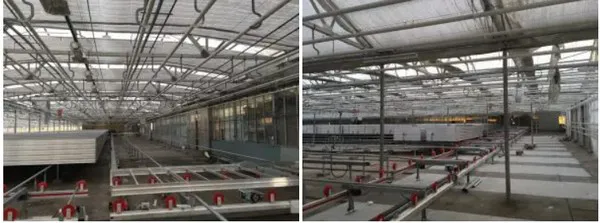

The new cultivation system for the Rocket Farms herbs greenhouse consists of about 2,000 growing tables with ebb & flood system, lifting and conveyor frames and stops, container drive units, push and pull units, a manual driven transport car, two overhead stackers, four fixed (de) stackers, an automatic container washer, all necessary electric installations, and an extensive, complete processing line for potting and packing the herbs. With this turnkey internal transport system, the production of the herbs has been automated from cultivation to packaging.

Complete, tailor-made processing line for pots of 9 and 14 cm

Video of the Potting Line in action:

Greater efficiency and innovation for Rocket Farms

"We aim to grow better plants with greater efficiency and to continue to pride ourselves on the ability to grow and ship products around the country," the Rocket Farms team states. The company is implementing new water retention and recapture systems to maximize water conservation as well as installing LED lights that will result in 48% energy savings. Additionally, they will have more room to train employees and create a positive and enriching work experience for all. Phase 2 for the expansion is currently being planned.

Video Rocket Farms installation:

For more information: Bosman Van Zaal

Bosman Van Zaal

+31 297 344 344

[email protected]

www.bosmanvanzaal.com