Australian and New Zealand fresh produce companies are being encouraged to utilise a new tool that uses mathematical formulas to model and predict the illness and absence of workers due to COVID-19, and ultimately hopes to reduce supply chain disruptions.

Food safety software company iFoodDecisionSciences (iFoodDS) has partnered with USDA and Cornell University to launch a free version of the Food Industry COVID-19 Control Tool (FIndCOVControl). iFoodDS Australian-based Regional Manager, Ilango Surendran says while it has only been used in the United States, so far, it is just as effective anywhere in the world.

"A shortage of products on the supermarket shelves is devastating for the retailers, producers, consumers and organisations working the supply chain from the farms to the retail DCs," he said. "I believe the usage of this software by growers can help them strategize how to minimise the risks for workers and continue their food production to ensure products reach the supermarket shelves."

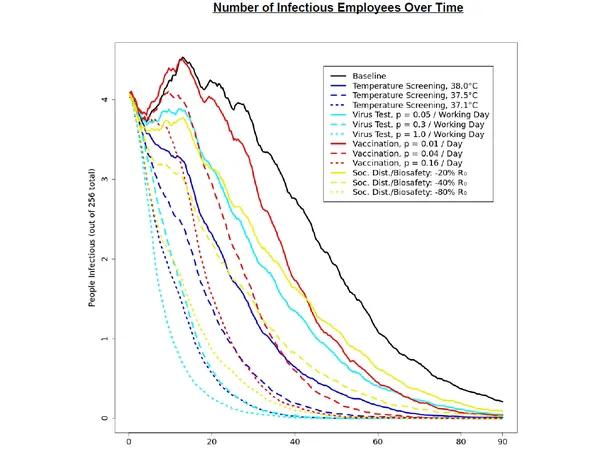

The software currently models the Delta variant, and the team is working on the Omicron variant, which should be available soon. The software is presently available for the produce farm but soon will cater for other agriculture commodities. After entering some information about the business, the user is provided with a report with model predictions to support decision making in their operations.

"The confidential report contains a lot of detailed data," Mr Surendran said. "It takes around an hour or two to generate depending on the inputs, and it runs through various scenarios. Even for things like the temperature of workers coming into the farm, allows you to predict what are the chances of other workers catching the virus if one person tests positive. Having all the temperatures of people in the company can allow the restriction of those with high temperatures, say over 37.5 onto the farm because they have a higher risk of transmission within the workforce. It can also look at other things like shared accommodation and vaccination. So, it provides information for an organisation to use to look at strategies to minimise COVID, while making sure production remains at an optimum."

Mr Surendran says the tool is free at least until August under the USDA funding and is currently used by several fruit and vegetable growers in the U.S. and he is hoping to collaborate with the fresh produce companies as they help with feedback, the evolution of the other agricultural commodities and refine its effectiveness moving forward, including in Australia and New Zealand.

"I am really waiting for them to start using it and provide some feedback on it," he said. "It is really simple and easy to use; once you put some facts and information in 'model selection', it gives you the prediction of various models. It is an easy and straightforward system to use, but again, it is there to help the companies to work out the staff who are affected by COVID (including a close contact), and what does that mean in terms of staying optimal with production levels to supply to retailers. If not, they can at least be upfront with their supply chain to say how much they are likely to be short, so everyone can prepare adequately. It should help ensure food is on the shelves at the supermarket."

The project stemmed from iFoodDS ongoing partnership with Cornell, who has been involved with other food safety predicting modelling systems such as the Environmental Monitoring Solution in the past to predict foodborne pathogens in various facilities.

"It's a tool that is freely available now, and we want to make sure that the farmers and the growers are aware of it," Mr Surendran said. "It's a very complex and very good model, at the end of the day it should help the growers, packers and retailers ensure that products are on supermarket shelves in these tough times. Hopefully, this tool can be used to model new COVID variants and other illnesses."

You can register and use the software at: https://www.foodcovidcontrol.com/FOODCTL

For more information

Ilango Surendran

Phone: +61 487 999 190

[email protected]

www.iFoodDS.com

https://www.linkedin.com/company/ifoodds