Killing bacteria and fungus with UV light without using a chemical liquid, UVRER has been doing it for more than 40 years and now has all kinds of solutions which are also widely used in horticulture. Besides water treatment, air purification, and surface disinfection, they now also offer the option to conserve liquids, like post-harvest liquids, to preserve flowers. With this treatment, the liquid can be used up to 7 to 8 days instead of only once, resulting in significant savings, explains Julio Asencio.

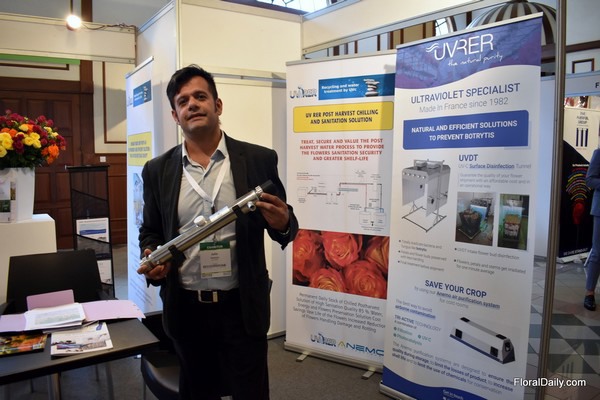

UVRER booth at the IFTEX 2023 in Nairobi, Kenya.

New UV-C conservation solution

With their UV-C sanitation of recycled nutritive solution for tomatoes - which was introduced in France in 2003, and then this technology spread to other countries, especially in Africa- they are now able to recycle and disinfect conservation liquids. "Nowadays, everything is about recyclability. With this UV treatment, the grower uses the liquids, then the remaining goes through a treatment plant where it is disinfected with UV. It is an installation at the farm, but as the conservation liquids can be used 7 to 8 times instead of only once, the ROI is huge. This treatment is a tailor-made turnkey installation adapted to the requirements of each farm. And the interest is high."

Ultraviolet and horticulture

And there are many more ultraviolet treatments they offer, and they are all adapted to the needs of horticulture, explains Julio Asencio. "Several growers in Kenya and Equatorial countries are already using our turnkey projects to disinfect recycled conservation liquids, nutritive liquids in hydroponic greenhouses, as well as our UVDT device to disinfect flower petals to get rid of botrytis fungus without using chemicals (for intake and before shipment steps). They are also disinfecting their cold room air with our devices to stock their flowers. We have other turnkey projects conceived by our Research and Development department to solve contamination and disinfection problems for transport, agriculture, grafting, seeds, cutting, and surfaces."

Customized solutions

Solutions are being customized. Julio Asencio: "We interact with people working on the farm, we understand their problems and interests, and we propose specific turnkey projects adapted to their needs. Using UV technology is trusting complete and suitable solutions to solve contamination problems in all areas of the production process, ensuring optimal preservation."

For more information:

For more information:

Julio Asencio

UVRER

Email: [email protected]

Kamal Rekab – Research and development, head of the North Africa Zone

Email: [email protected]