Exploring how data from sensors, satellites, and drones can be harnessed for digitalization in horticulture is the focus of the Triple Thrive Data project, which was

presented at the horticultural business of Thomas Viehweg in Issum, close to the Dutch border with Germany. The German-Dutch growers' cooperative Paletti Growers initiated and supported this project. Invited by the Agropole Innovates project, Brightlands Campus Greenport Venlo, the municipality of Venray, and Agrobusiness Niederrhein invited the association to showcase their findings at the nursery in Issum.

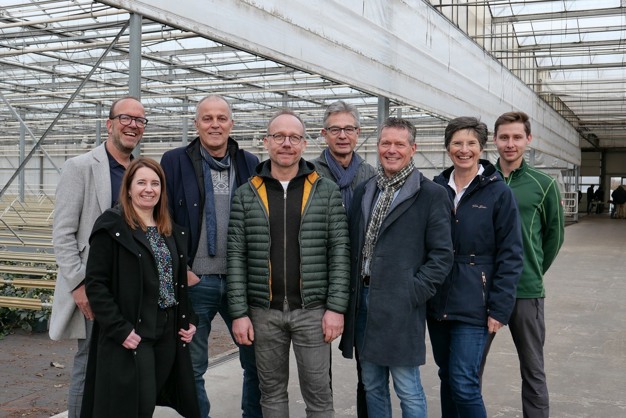

From left to right: John van Helden - Yookr, Yvonne van der Velden - Brightlands Campus Greenport Venlo, Marcel Claus - Municipality of Venray, Thomas Viehweg - Gartenbau Viehweg, Wouter Middel - W2R Drone Projects, Eric Brouwers - Paletti Growers, Dr. Anke Schirocki - Agrobusiness Niederrhein, Lukas Viehweg - Gartenbau Viehweg

Triple Thrive Data aims to gather data to develop a data-driven dashboard for growers that enables predictions about, i.e., flowering, disease occurrence, or nutrient deficiencies. The system learns from the past and predicts the future. "We employ artificial intelligence to make horticulture more sustainable, as it aids in preventing failures, operating more efficiently, and saving on water, fertilizers, and crop protection products, benefiting the environment," explains John van Helden, director of the Dutch company Yookr, which significantly advances developments in this area.

Future predictions are still under development, but it is already possible to achieve remarkable results in plant cultivation with the use of smart sensors. Attendees were shown what is currently achievable. Thomas Viehweg has been using sensors and analysis systems from Yookr in his nursery in Issum for three years. The nursery utilizes twelve sensors that monitor soil moisture, temperature, nutrient content in the substrate, pH value, and, for example, the amount of fertilizer in the fertilizer tank. Everything is displayed on a dashboard on a laptop.

The grower then sets the threshold values themselves: at what stage of substrate dryness should a plant be watered? How much fertilizer solution should be in the tank before a warning is displayed? "Based on our cultivation knowledge, we first determine the threshold values and then enter them into the computer. From that moment, the gardener receives a notification as soon as watering is needed or the fertilizer tank needs refilling," explains Thomas Viehweg.

His staff immediately saw the benefits and did not need to be convinced to use the system. "Watering is much quicker, as this information significantly reduces the need for personal plant inspection," says Patrick Meurisch, gardener and cultivator at Viehweg Nursery. "It also has a practical advantage: on Sundays, I first check my app, and if the plants are still moist enough, I can stay in bed an hour longer before I have to go to the nursery," he reveals.

Wouter Middel from the Dutch company W2R Drone Projects reported on everything possible with drones. His work is also part of the Triple Thrive Data project. W2R Drone Projects aims to further develop drone technology and optimize flying in, among other settings, greenhouses. They also offer the use of drones as a service. A drone can collect multispectral data, thermal data, or images. This creates visual information, which is usually invisible to the human eye. "You can use the technology to tell how the plant is feeling before it becomes visible. This way, you can assess the health of the plant early on," says Wouter Middel. He gives an example of a flight over a soccer field. The images showed signs of a fungal infection. "However, nothing was visible to the naked eye. "The client was skeptical of the drone flight results and decided not to act. The reliability of the drone flight results was proven when, sometime later, large areas of the soccer field became visibly infected," Wouter adds.

As part of the Triple Thrive Data project, the developments have also been tested in a Dutch horticultural business for three years. "By using this technology, we were able to save up to 21% on water, fertilizers, and pesticides. That's already a fantastic result," says John van Helden. "The next goal is to be able to display data and indicators on plant growth, real-time photos, and plot maps in the dashboard from the second half of 2024," he adds.

New developments are needed to make even better predictions. The foundation has been laid; now it's time to build upon it. "We are already quite good at predicting harvests for tomatoes," explains John van Helden, but for further development in, for example, ornamental horticulture, he needs the practical experience of growers. He collects their questions to feed the system with the necessary data. "German-Dutch collaboration offers a lot of potential that we, as growers in the border region, must seize." John van Helden and Thomas Viehweg are convinced of this and also refer to the successful cooperation between German and Dutch growers in the Paletti Growers network.

"We're investing in our future," agree the visitors. Yvonne van der Velden, Business Developer at Brightlands Campus Greenport Venlo, recognizes the importance of these developments. "AI is the future, also in horticulture. As a partner in the Interreg project Agropole Innovates, our goal is to promote such developments in the border region through knowledge transfer, networking, and initiating projects. We will continue to follow the theme of this meeting with interest," she states.

For more information: www.agrobusiness-niederrhein.de