"Growers are increasingly encouraged to adopt bedding packs that meet the latest environmental standards. Especially so in the UK, which I think, is a bit ahead of other countries when it comes to recyclability. Yet, a lot of growers think that when they swap to another bedding pack, they have to switch machinery too. This switching of machinery is far from efficient, and it can be avoided," states Peter Wessel, Sales Manager UK at Modiform."

Modiform is a Dutch-based, internationally active company that seeks to provide solutions in cultivation, transport, and packaging systems for the horticulture supply chain based on recycled raw materials.

In the light of ongoing developments in the fields of recycling and automation, Modiform recently developed their 76-bedding pack range which aims to allow growers to smoothly switch from one bedding pack to another. In this article Peter will tell us more about this range and recycling in the UK.

From PS to PET

Peter highlights that recyclability currently is a hot topic in the UK, saying: "Since five or six years, there's a lot of pressure for people to change. The government, retailers, TV programmes, and documentaries like those from David Attenborough all draw attention to the issues of sustainability and recycling."

He points out that this pressure, had considerable implications for the bedding-pack industry. "In the UK, manufactures used to produce bedding packs made from black PS. Things changed when retailers and the government put more pressure on recycling, and recyclable plastics became the standard."

At Modiform they decided to switch from PS to recyclable PET, mainly because PS in any colour will not get recycled at kerbside. "We opted for PET as drink bottles are among the most recycled products, and we found that the transparent green works perfectly well. Despite the transparency the roots do excellent. Moreover, customers appreciate the fact that they now can see the roots through the bedding pack, and when they realize that this is all made from drink bottles, this gives another dimension."

A focus on efficiency

In the past few years, Modiform expanded their range of recyclable PET bedding packs, which today counts 35 products. One of the latest additions of this assortment is the 76-series which were developed in cooperation with grower Sam Thompson from J&J Thompson.

Peter Wessel and Sam Thompson with the Modiform 76-bedding pack range

Peter: "Thompson was looking for bedding packs made from recyclable PET, but that involved very little change to his machinery. This resulted in the 7601, 7602 and 7604 which all have the same outer dimensions. Even the handle spacings are identical.

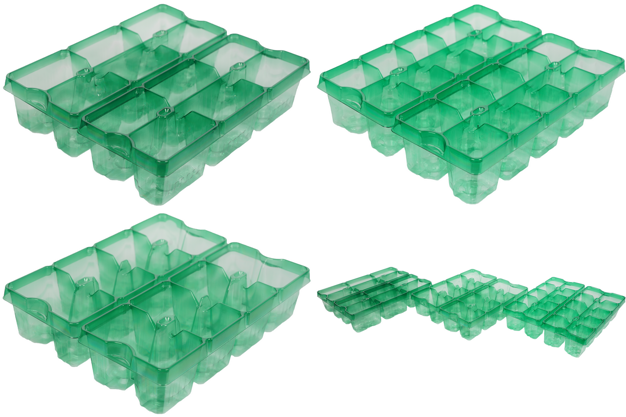

Clockwise: the 7601, 7602, 7604, and all of the three bedding packs together

In other words, growers that use these bedding packs only have to change the program on the transplanter. There is not any downturn, or any additional labour needed, making growers more efficient. This is key, the more so because it has become hard for UK growers to bring labour from abroad since Brexit."

Kerbside recycling and further experiments

That's not to say, that the Modiform doesn't see any further room for innovation and change. They would love to see that PET-bedding packs are not only commercially recycled but also at kerbside.

"Our 76-bedding packs are PET-recycled, and independently certified for kerbside recycling. We feel that bedding packs have to be recyclable at kerbside because they end up at the consumers, who put them in the recycle bin. In that respect Modiform welcomed last week's announcement, by the Horticultural Trade Association (HTA), that all non-black, recyclable PET or PP plastic plant pots will be accepted in household kerbside recycling in England."

Peter further adds that Modiform will continue to experiment with bedding pack materials with the goal of keeping up with future developments. "It's going to be interesting to see what's happening in the future. PET is the perfect polymer for bedding backs. It will not change overnight. But if the material of bottles changes in the future, our source of material will dry out. For this reason, we are always experimenting with different materials, not just plastics. We think that pots will change first, it will show where the industry will go."

For more information:

Modiform

[email protected]

www.modiform.nl