In recent years, many investment discussions have increasingly focused on labor-saving solutions. With rising labor costs, the return on investment becomes more attractive. Following the announcement of a 10% increase in the collective labor agreement wages in the Netherlands by 2025, WPS has already observed a noticeable uptick in inquiries.

Conré Oostrom and Digna van Zanten

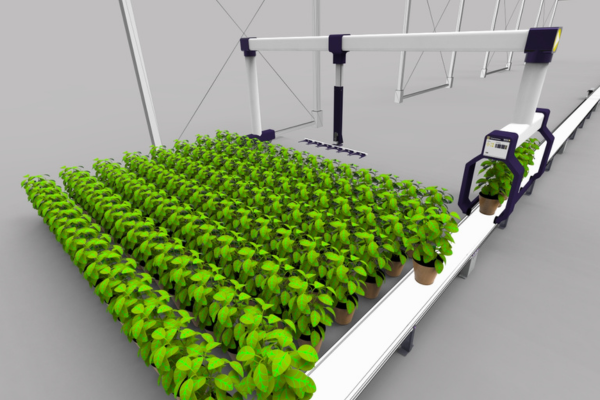

In that sense, the launch of their FloorManager could not have come at a better time. What does the FloorManager entail? WPS is marketing this solution to take a lot of work off your hands through gantry automation. The gantry automation will initially be used for putting down, widening, and picking up potted plants. "But the possibilities are many," Digna van Zanten, owner WPS, explains to us. "Think of the gantry as a platform to use it for various purposes. Besides the above purpose, it can also be used for crop care, crop protection, monitoring, pruning, etc. As standard, the gantry is now lightweight and flexible. Depending on the purpose, we customize it."

FloorManager

The system is patented. The FloorManager connects to both WPS and other systems. It is flexible.

The whole idea started with Patrick Zuidgeest of Bestplant and co-sponsored by Innovation Quarter. Digna: "We started thinking and developing together and have completed the first tests. By now we have received quite a few applications and it is time to go public. The gantry will be used for both plant research facilities and pot plant companies. For plant research, we work together with Hiphen and Phenovation for the right application of sensors."

Michael Meijler (R&D coordinator WPS and Patrick Zuidgeest of Bestplant)

The Netherlands versus North America

Important markets for WPS are North America and the Netherlands. Digna very briefly summarizes how quickly and many labor costs can be saved in America: "There, 'Conveyors are the way to go'. In North America, once growers take a look in each other's greenhouses, the adoption of conveyors in the potted plant sector starts to gain momentum. "They see that it works, and when they realize the savings, they become convinced of its value," she explains.

Automated pot plant packing

The FloorManager is a brand new, but more labor saving initiative are coming. The next step? Automating the packing of orders. According to WPS, this process could soon be fully automated, further streamlining operations and reducing manual labor.

For more information:

Digna van Zanten

WPS

Tel: +31 174 671 371

[email protected]

www.wps.eu